- Home

- /

- Services

- /

- Laboratories

- /

- Asphalt Lab

Asphalt Lab

Asphalt Pavement Testing, Reporting, Mix Design

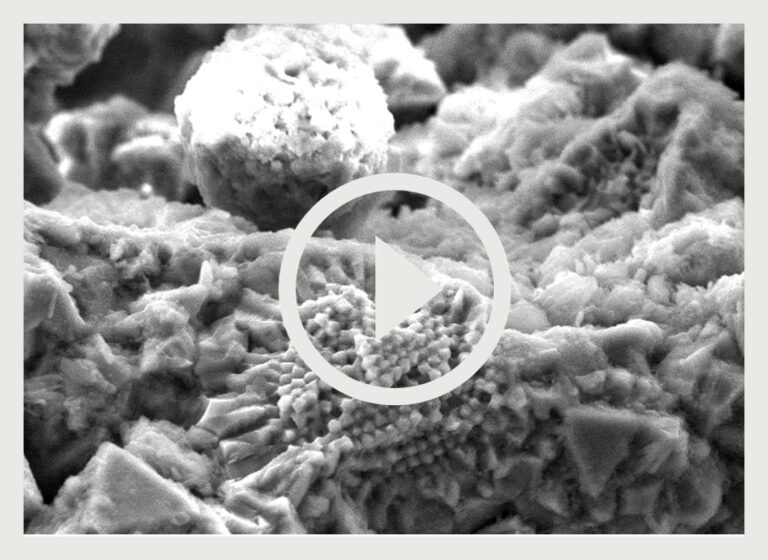

From highways to parking lots, we expect asphalt pavement to provide a solid, long-lasting driving surface. By testing the materials used and the final asphalt mixture – before it goes on the road – contractors can be sure the pavement will meet requirements.

The AET Asphalt Laboratory is an accredited bituminous laboratory, located in Saint Paul, Minnesota. We provide asphalt materials testing, quality assurance testing, and asphalt pavement mix design for the construction of roadways, parking lots, railways, and runways – across the nation and around the world.

AET uses the latest asphalt testing technologies

Our lab can meet your everyday testing needs but we also have the capability to support special research studies on bituminous materials. Some of our specialty equipment includes the Hamburg Wheel Tracker, dynamic modulus testing, DCT, IFIT, inner-layer shear strength testing.

Established 1990, we maintain the best-equipped bituminous testing laboratory in the Upper Midwest.

Our lab team is highly experienced and dedicated to this core specialty. Their combined knowledge base and use of the latest asphalt testing technologies means you receive accurate, thorough reports and meaningful consultation.

We have “big-picture” understanding of asphalt pavement testing

The AET Asphalt Lab team members have decades of experience meeting client needs and asphalt specifications. We have the expertise and background to help our customers understand their specifications and testing needs and provide the most cost-effective approach for complying with testing standards and requirements.

Each year, our lab team tests thousands of pavement samples from roadways and runways. We understand the urgency of receiving testing results in a timely manner, but we do not cut corners to save time. We balance our strong focus on quality and compliance with the practical needs of the client to maintain their timelines and budgets.

AET asphalt mix design expertise — recognized around the world

Our asphalt mix design team works closely with AET specialists in chemistry, cement/concrete testing, and nondestructive testing and evaluation. Where needed, we also consult with AET pavement, geotechnical, construction materials testing, petrography and environmental professionals. Drawing from this cross-disciplinary team, we can provide a comprehensive, thoughtful approach for your mix design project.

We work on projects of all sizes for clients around the world. Please us to discuss your testing needs or for responsive field observation and troubleshooting on existing projects.

Asphalt testing and mix design services

Basic Asphalt Testing

- Extraction

- Gradation of extracted aggregate

- Specific gravity

- Density

- Stability

- Flow

Specialty Asphalt Testing

In addition to basic tests for extractions, gradations, and Gyratory and Marshall mix designs, AET also has the knowledge and tools to conduct more sophisticated and accurate testing.

- Disc-shaped Compact Tension testing (DCT)

• Hamburg Wheel Rut testing

• Low Temperature Cracking (AASHTO T322/ASTM 6931)

• Resilient Modulus testing/Dynamic Modulus testing (SPT)

• Semi-Circular Bending Test (SCB)

• Tensile Strength Ratio testing (TSR) - Bituminous Extraction (Ignition and Chemical)

- Volumetrics

Pavement Field Testing

- Falling Weight Deflectometer testing (FWD)

• Ground Penetrating Radar - Dynamic Cone Penetrometer

- Light-Weight Deflectometer testing (LWD)

- Condition and Smoothness Testing

Base and Subgrade Materials testing

- R-Value and CBR testing

- Resilient Modulus Testing (AASHTO T307 modified)

Mix Designs

AET also provides customized balanced mix designs to meet project needs.

- Foamed Asphalt Mix Design

• Hot-mix asphalt (HMA) Mix Design - Superior Performing Asphalt Pavements (SuperPave) Mix Design

- Stabilized Full Depth Reclamation Mix Design

- Cold-in-Place Recycling Mix Design

- Soil-Cement Stabilization Design

Contact a Laboratory Professional

Related Services

Laboratory Projects

We are excited to continue recognizing all the extraordinary women on team AET who contribute to our company, present and …