Grain storage and handling is big business. Issues such as storage capacity and speed to market are increasing demands on producers and suppliers. As such, storage options are increasing in scale and therefore need specialized design and planning.

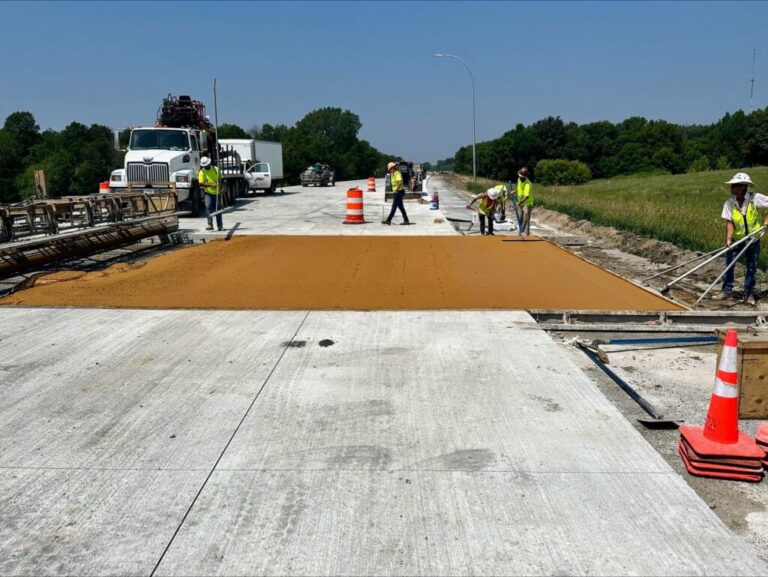

Crystal Valley developed a large new grain storage and handling facility consisting of three 135-foot-diameter dry storage steel bins, two 36-foot-diameter blending bushel bins, one 72-foot-diameter wet storage steel bin, a conveyor and tower, truck receiving pit, scale building and ground storage pile area. Roadwork to support the project consisted of concrete pavement or gravel surfaced pavement and an associated loop railroad with steel tracks supported by crushed rock ballast — on a 2-foot cut to a 10-foot grade increase.

To evaluate site suitability, AET’s Geotechnical Group performed soil borings and a preliminary geotechnical report. Once the site was approved, we followed with extensive soil borings, Seismic Cone Penetrometer Test (CPT) soundings as well as the geotechnical engineering analysis and report. Once earthwork began, AET performed excavation observations and field and laboratory testing on fill soil. We documented over 300 field density tests and 14 modified proctors and sieve analysis tests during the earthwork grading on a part-time to full-time basis. Our Construction Materials Group employed field and laboratory concrete testing services for 72 sets of concrete cylinders.

The project celebrated its grand opening September 10, 2014.

For more information about these services, visit our Geotechnical page and Construction Materials page.